Why chemical etching is best for perforated metal mesh manufacture

Perforated metal mesh is widely used across various applications and industries, from speaker covers, filters and air intake grilles in the aerospace and automotive sectors to craniomaxillofacial implants, stents and sieves in the medical industry.

In this article, we explore the optimal machining process for manufacturing complex micro mesh components and how Precision Micro’s advanced photochemical etching service enhances their production.

What is perforated metal mesh?

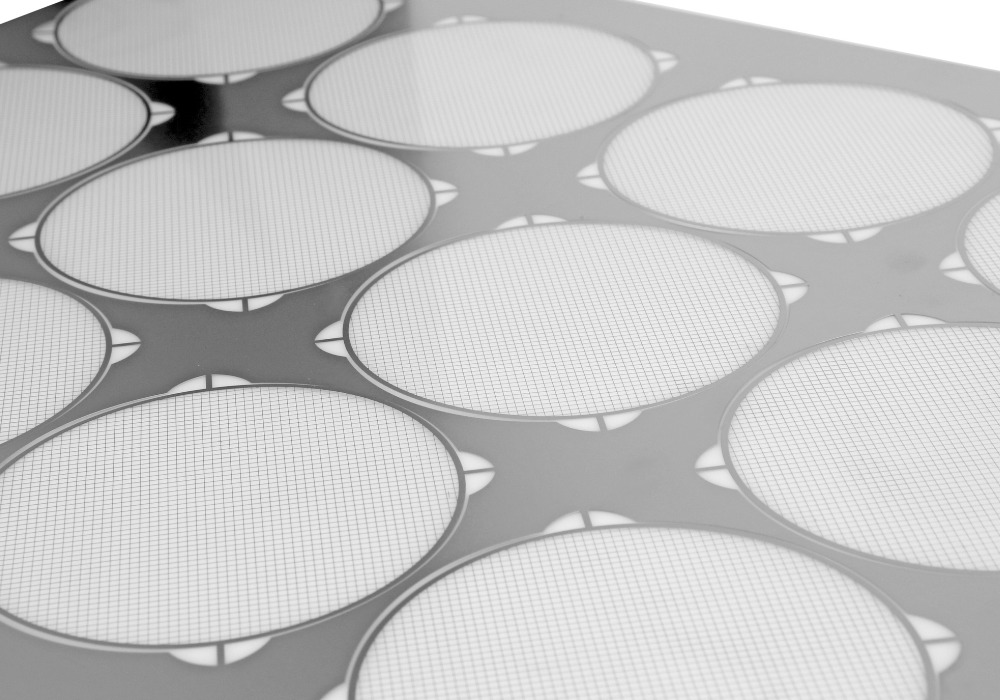

Perforated metal mesh is a sheet of metal with a pattern of holes, slots or decorative shapes. It is widely used in various industries due to its versatility, durability and aesthetic appeal. The perforations allow air, light, sound, and liquids to pass through while filtering large particles and retaining strength and structural integrity.

What metals are used in manufacturing perforated metal mesh?

Sheet metal mesh can be manufactured from various metals, including stainless steel, aluminium, carbon steel, brass, copper, titanium and nickel. Each material provides distinct properties, such as corrosion resistance or strength, with the choice of material determined by the specific application requirements.

How is perforated sheet metal mesh manufactured?

Perforated metal mesh sheets are typically produced using traditional machining methods like stamping, laser cutting and water jet cutting. However, these methods can lead to material distortion, burrs and stresses, affecting component integrity. Laser cutting and water jet cutting, with their high temperatures and use of abrasive materials, can also negatively impact the machining of micro metal meshes. Moreover, these traditional processes often face challenges in achieving precise designs and are limited in the types of metals they can machine effectively.

How chemical etching enhances perforated micro metal mesh manufacture

Unlike traditional sheet metal machining methods, chemical etching preserves the properties of sheet metal meshes and eliminates the risk of material distortion. By selectively dissolving material using chemical etchants, this process ensures optimal part performance and overcomes the inherent challenges associated with conventional methods.

Economic cost

Photochemical etching is an economical manufacturing technique that replaces traditional hard tooling with digitally produced photo tooling. Acting as stencils, these tools can swiftly and precisely transfer complex CAD designs onto sheet metal, preparing it for chemical etching at a fixed cost.

Intricate mesh patterns

Chemical etching offers unparalleled design flexibility and complexity. It excels in producing micro metal mesh with extremely fine holes and intricate geometries, achieving openings as small as 0.1mm and consistent pore sizes within +/-0.025mm. These capabilities are often challenging or impractical to achieve using conventional machining methods when cutting holes of varying size on the same part.

High-quality metal mesh

Unlike conventional cutting, chemical etching consistently produces high-quality perforated metal mesh sheets by using chemical etchants to dissolve material from the metal sheet. This process eliminates the physical contact and high temperatures associated with stamping, laser cutting, and water jet cutting, ensuring that all metal mesh components are burr and stress-free, with zero material distortion or degradation.

Scalability

The photochemical etching process offers engineers scalable production capabilities, from prototyping to large-scale manufacturing of perforated metal mesh. By utilising digital tooling and etching all component features simultaneously, this method ensures uniformity, consistency and reduced lead times across production runs.

Why use Precision Micro to supply your perforated metal mesh?

With over 60 years of expertise in chemical etching, Precision Micro delivers advanced manufacturing services for perforated metal mesh. Our process surpasses traditional perforating techniques by offering superior speed, flexibility and cost-effectiveness. We specialise in machining intricate designs with high precision, ensuring optimal performance and quality, meeting the diverse needs of various industries.

Conclusion

Photochemical etching is the ideal manufacturing process for machining perforated metal mesh sheets, capable of creating hole sizes and geometries that conventional machining methods cannot achieve. This cost-effective and scalable process, regardless of component complexity or production volume, leverages Precision Micro’s expertise and advanced services to ensure high-quality metal mesh production with reduced time-to-market.

Learn more about etching perforated metal mesh, download our free application note today!

Chemical Etching Whitepaper

Learn how chemical etching can overcome the limitations of traditional sheet metal machining technologies.

Download