Electric Motor Laminations

Our speciality lies in the production of motor laminations that are meticulously crafted to meet precise specifications. With our chemical etching service, we excel in providing unparalleled speed and quality throughout the manufacturing process.

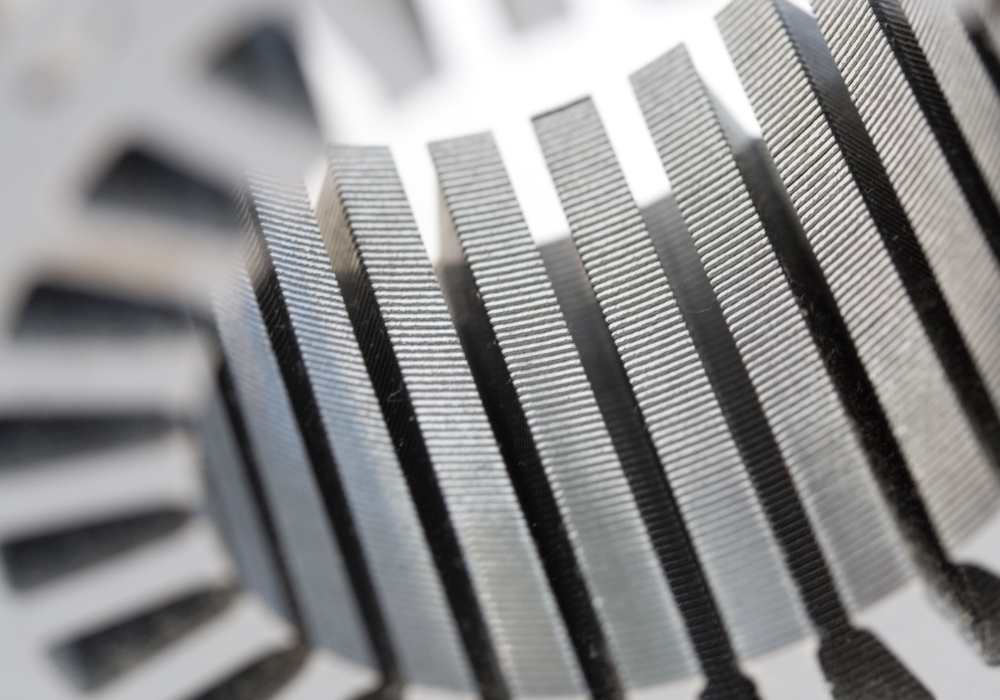

Traditional motor lamination stamping

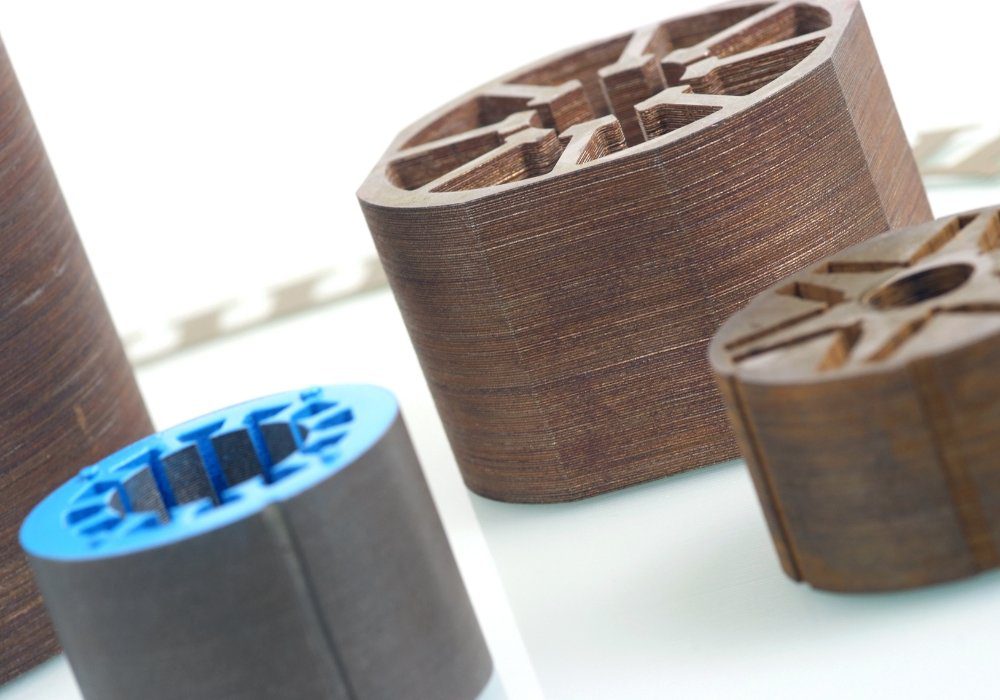

Motor laminations, also referred to as silicon or electrical steel laminations, are produced through the use of electrical steel sheets. The metal laminations cut from these sheets are then stacked and bonded together to form the core of an electric motors stator and rotor.

While traditional machining methods like stamping are commonly used to profile metal laminations, this approach can introduce residual stress that can negatively impact the magnetic properties of electrical steels. Additionally, it may lead to the formation of burrs, which can pose challenges during the winding process.

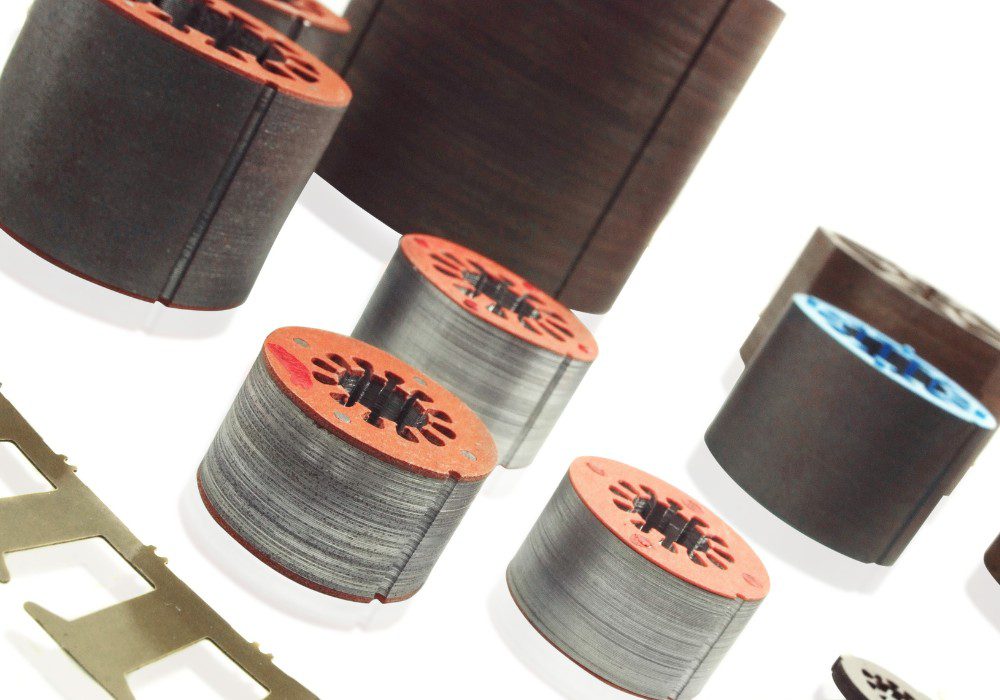

Chemical etching motor laminations

By utilising the benefits of chemical etching for producing motor laminations, manufacturers can achieve improved performance, cost savings and faster production times while maintaining high-quality standards.

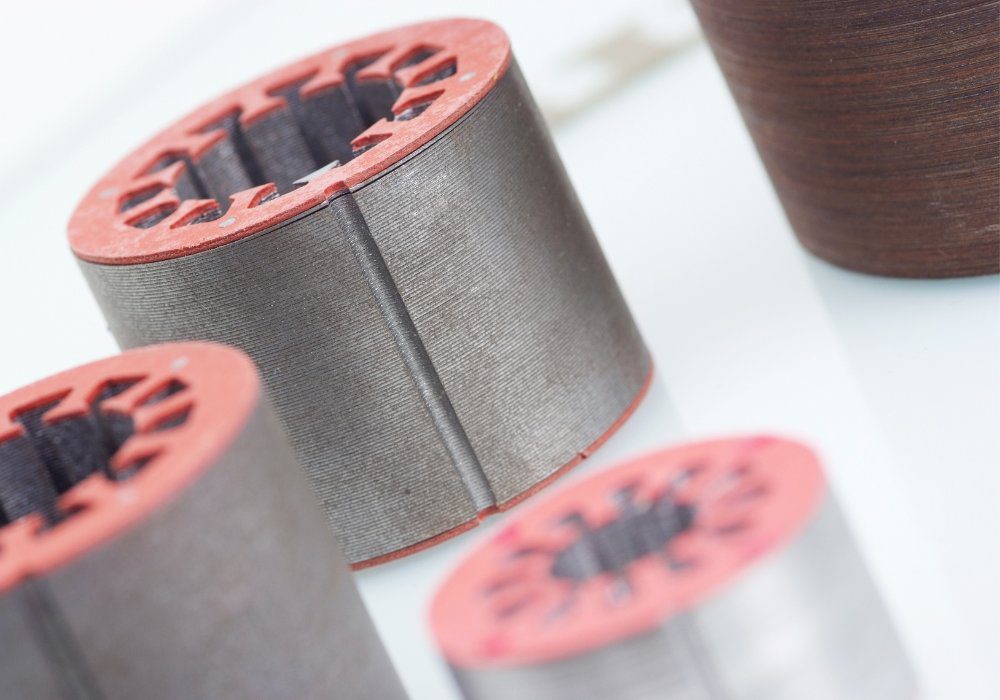

Chemical etching preserves the magnetic properties of electrical steels by avoiding the introduction of residual stress. This ensures optimal motor performance. Additionally, the process produces burr-free laminations with precise profiles, eliminating the need for additional deburring processes.

A cost-effective solution for prototype development

Chemical etching is a cost-effective solution for prototype development as it eliminates the need for expensive tooling. This streamlined process enables faster supply of loose metal laminations and lamination stacks, reducing costs and facilitating quicker iterations. This supports agile product development by allowing for efficient design modifications and accelerated testing and validation cycles.

Benefits

Low-cost tooling

100% stress and burr-free

Accuracy to ±0.005mm

Fast prototyping

Consistent quality & repeatability

Chemical etching guarantees consistent quality and repeatability in manufacturing motor laminations from electrical steels, cobalt and nickel alloys, with thicknesses ranging from 0.1mm to 1.0mm. This process enables precise control over manufacturing parameters, resulting in laminations with uniform characteristics and an accuracy of ±0.020mm. For high-end motors that demand exceptional precision, we can further enhance accuracy by combining chemical etching with wire EDM.

Electric Motor Laminations Application Note

Discover how you can unlock the benefits of chemical etching when producing motor laminations.

Download