Printed Circuit Heat Exchangers

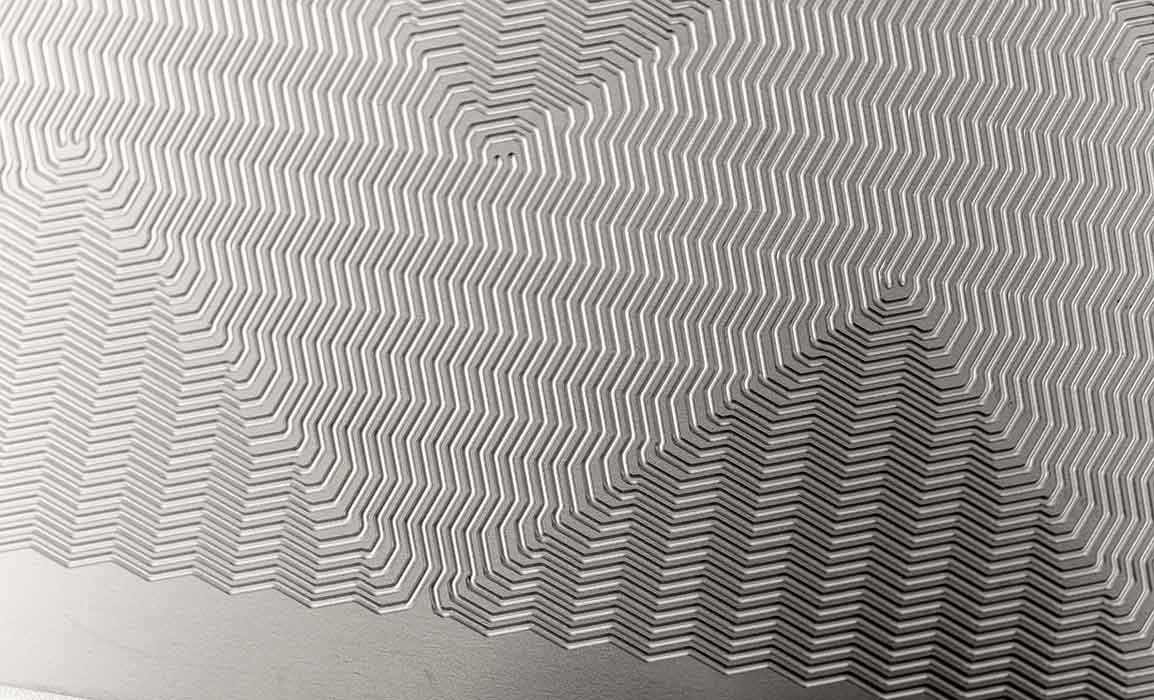

Photo-etched flow plates for PCHEs with exceptional channel accuracy.

Request Pricing Application NotePrecision Micro stands as the global leader in manufacturing flow plates for printed circuit heat exchangers (PCHEs), offering unmatched volume capacity and exceptional channel accuracy.

What is a printed circuit heat exchanger?

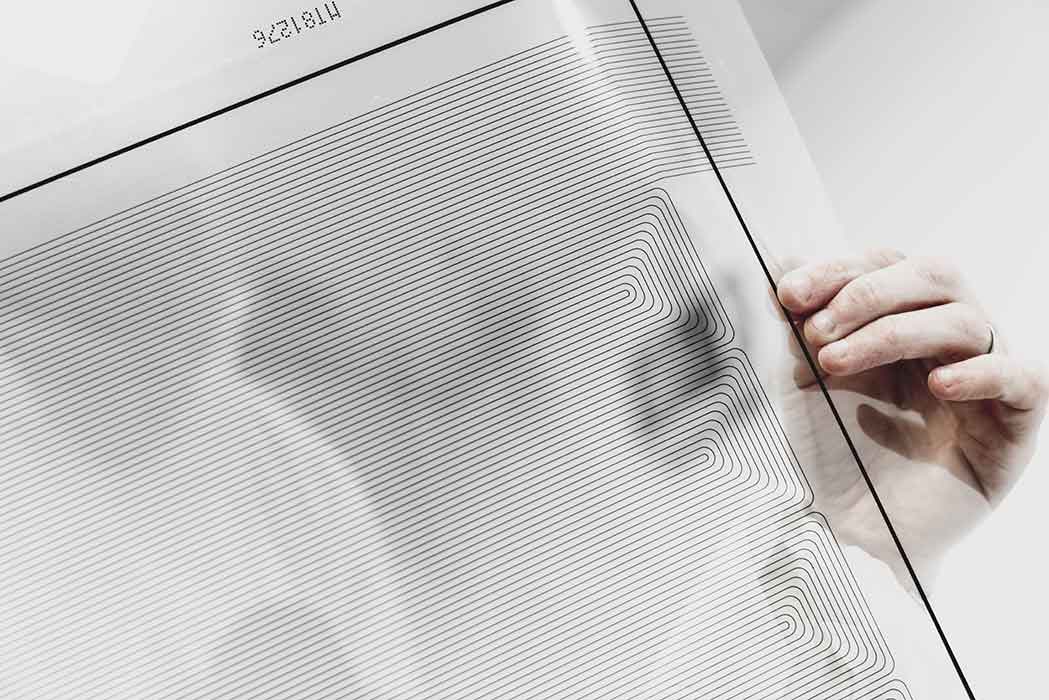

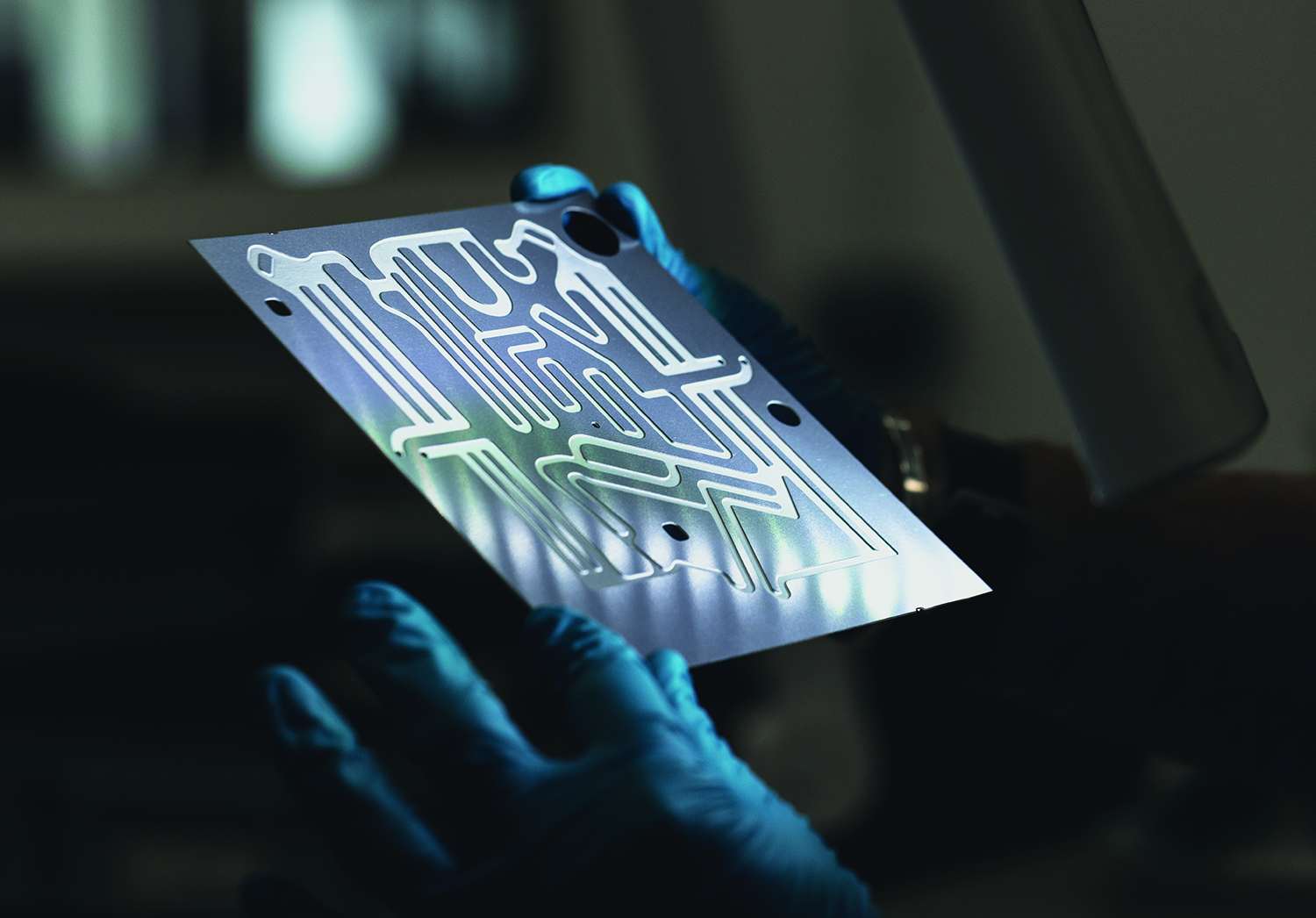

A printed circuit heat exchanger combines chemical etching and diffusion bonding technologies. Flow channels are chemically etched onto metal plates, which are then stacked and solid-state joined through diffusion bonding to form a single block.

Precision Micro & PCHE technology

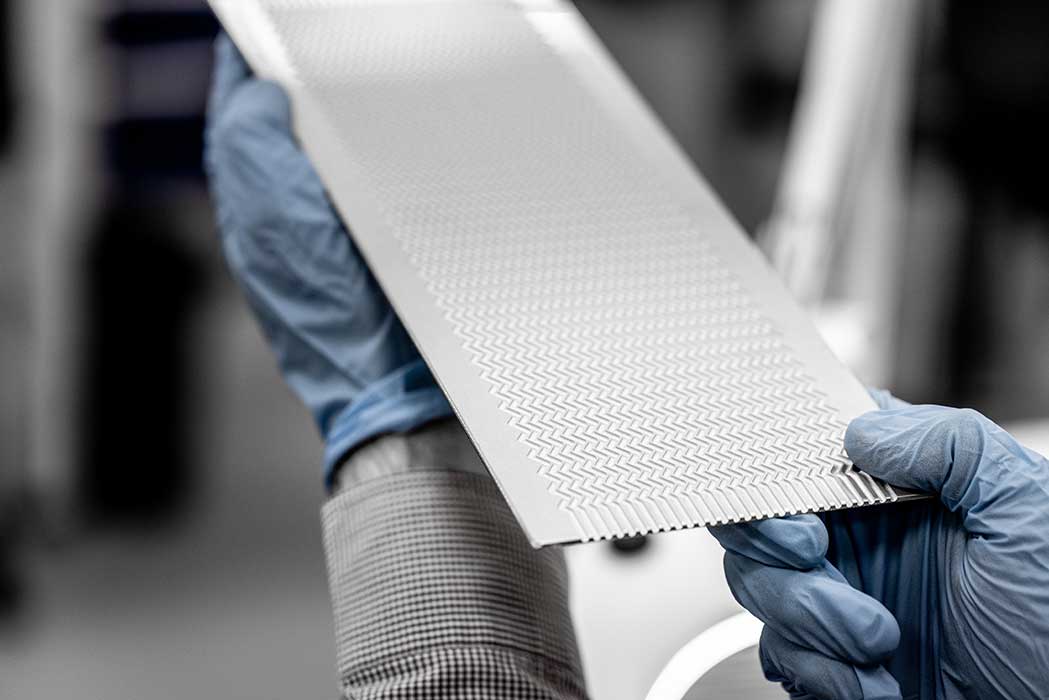

Since the 1990s, Precision Micro has been a pioneer in PCHE manufacturing. Our market-leading chemical etching service provides volume versatility, catering to fast, cost-effective prototypes to high volume production. Our production etching plant is capable of supplying etched flow plates up to 1500mm x 600mm in size and thicknesses up to 2.5mm.

Etched flow plate materials

Our chemical etching process is compatible with a wide range of metal types and grades. While 316-grade stainless steel is commonly specified for plate and printed circuit heat exchanger plates, we can also work with lightweight, corrosion-resistant metals like aerospace grade aluminium.

Benefits

Leading name in PCHE flow plate manufacture

Largest etching capacity

Exceptional channel accuracy

Diffusion bonding service

Diffusion bonded heat exchangers

With longstanding partnerships with diffusion bonding technology leaders, we provide a comprehensive one-stop-shop for chemical etching and diffusion bonded printed circuit heat exchangers. Our expertise enables seamless integration of both processes, ensuring quality and efficiency for our customers.

Heat Exchangers Application Note

Learn more about the benefits of using chemical etching to produce heat exchanger flow plates

Download