Copper Etching

Comprehensive copper etching service that covers both standard and specialised copper alloys.

Contact UsPrecision Micro offers a market-leading copper etching service, providing rapid, miniaturised and precise components etched from various copper and copper-based alloys, such as beryllium copper, nickel silver, brass and phosphor bronze.

CONVENTIONAL COPPER MACHINING LIMITATIONS

Using conventional machining methods like laser cutting to cut copper-based alloys has always posed challenges due to their reflective nature.

Similarly, stamping and waterjet cutting can adversely affect material flatness, cut quality and overall efficiency due to the impact forces involved in these processes.

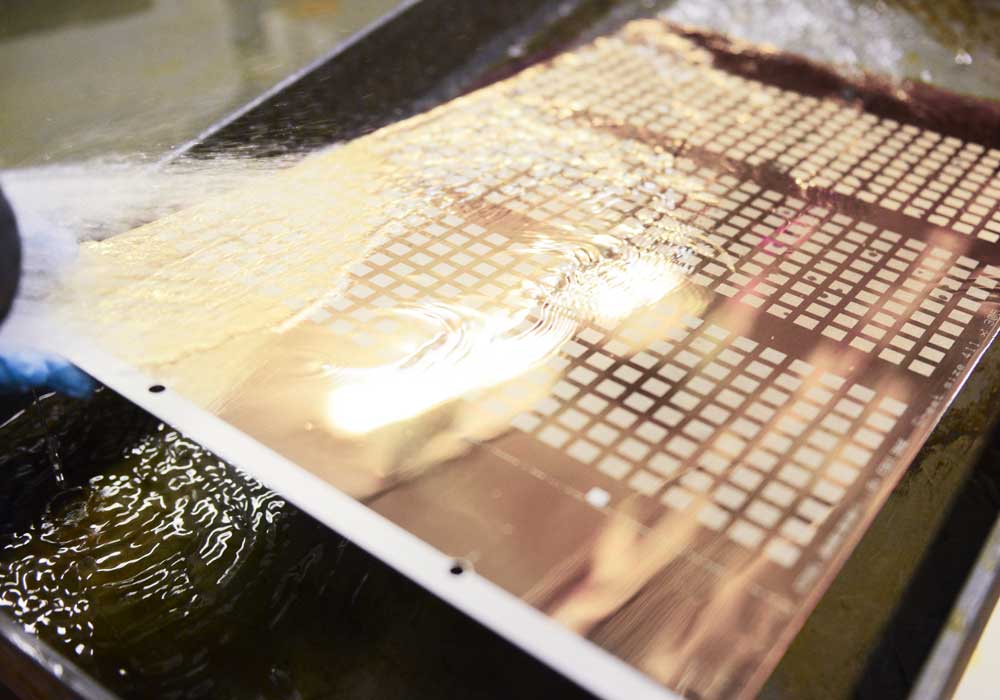

CHEMICAL ETCHING COPPER

Chemical etching uses a controlled chemical reaction, using sustainable etchants to selectively dissolve material from a metal sheet. This non-thermal, non-contact process guarantees burr-free, stress-free and flat copper components without altering material integrity.

This process also offers a perfect solution for miniaturised copper parts with its capability to achieve intricate designs, tight tolerances and precision accuracy to within ±0.020mm.

COPPER GRADES SUITABLE FOR CHEMICAL ETCHING

We offer a comprehensive copper etching service that covers pure copper as well as standard and specialised copper alloys known for their hardness, resistance to corrosion and wear-resistance properties.

| Material | Grades/types |

|---|---|

| Beryllium Copper | All grades |

| Brass | All grades |

| Copper | All grades, including oxygen-free |

| Ferry | – |

| Nickel Silver | All grades |

| Phosphor bronze | All grades |

ETCHED COPPER COMPONENTS

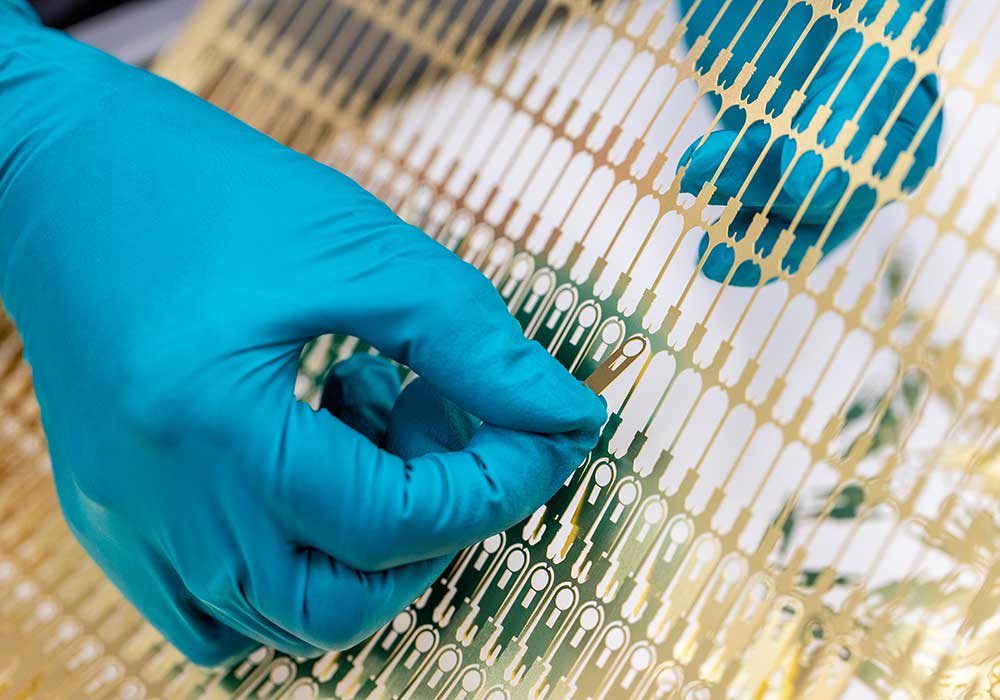

Copper stands as one of the most widely used metals, with thousands of components etched every month to serve various engineering applications across automotive, aerospace and many other precision engineering industries.

Copper’s high conductivity, durability, ductility and malleability make it an excellent choice for producing electronic components, which can also be formed, finished and plated where required.

Some of the typical copper components we produce include:

- Contacts, pins, and connectors for electronics

- PCB shielding cans

- Fingerstock gaskets

- UHF/microwave antennas

- Lead frames

- Busbars for electric power distribution

Chemical Etching Whitepaper

Learn how chemical etching can overcome the limitations of traditional sheet metal machining technologies.

Download