How much does chemical etching cost?

As with any metal machining process, there are numerous factors to be taken into consideration when costing chemical etching. In this post, we explore these in more detail.

What makes up the cost of chemical etching?

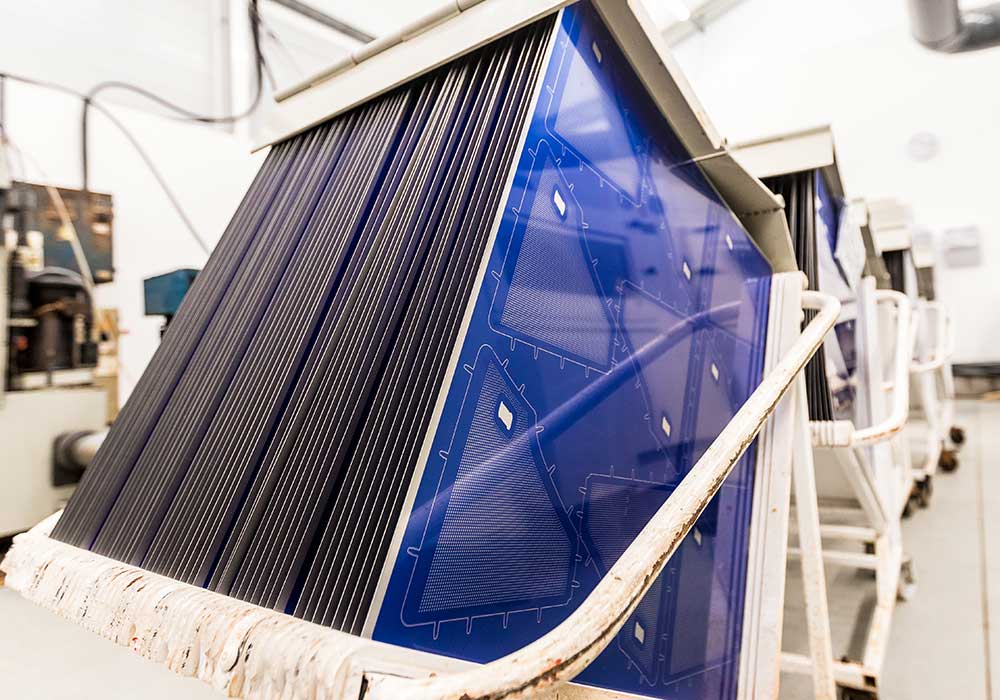

Chemical etching, also known as photo etching, metal etching or photochemical machining, uses etchant chemistry (typically ferric chloride) to selectively remove metal from a sheet printed with the component design.

The overall cost of chemical etching includes:

- The sum of materials, including metal, photoresist and chemistry

- Technical costs and process time

- Overheads including chemistry, water, power and waste treatment

- Labour, including engineering

- Standard service and administration costs

Metal types and quantities

The cost of sheet metals can vary considerably. Standard grades of stainless steel, nickel and brass are generally cheaper than exotic alloys.

At Precision Micro we process more than 100 tonnes of sheet metal each year across more than 2,000 metal types – more than any other chemical etching supplier.

This means customers benefit from both our purchasing economies and the wide variety of metals we hold in stock, removing the need for us to pass on expensive supplier minimum order charges.

Metal thickness

Material thickness is another important cost consideration.

The thicker the part the longer it takes to etch, meaning the process is usually uneconomical for components above 1.5mm thick.

Labour, sheet size and sheet yield

The chemical etching process consists of:

- Metal sizing and tooling

- Cleaning

- Photoresist lamination

- Printing

- Developing

- Etching

- Stripping and finishing

The labour input in all of these stages remains pretty much the same regardless of sheet size, so the larger the sheet and the smaller the part size, the lower the unit cost.

Components are priced by the sheet, unlike laser cutting, which is a linear process charged by time and therefore by the inch.

Simultaneous machining of components means chemical etching handles increased complexity at no extra cost. It also allows for multiple part designs to be prototyped on a single sheet.

Volume and set-up costs

When compared to technologies such as stamping, chemical etching can be extremely cost-effective, due in no small part to the use of digital phototooling.

Stamping requires hard tooling, which adds increased cost and time.

Phototools are low-cost – starting from less than €100/$120 – and extremely quick to manufacture, often less than 1 hour.

Chemical etching can accommodate design and tooling re-iterations that would be prohibitive when hard tooling is used, making the process ideal for prototype to production manufacture.

Summary

If enough thought is given to the key factors that influence the cost of chemical etching, such as the material to be used, part size and thickness, the process can be the most cost-effective metal machining technology available today.

In addition, by partnering with an established supplier that has the buying power, stock availability and process automation, you can ensure price competitiveness.

Chemical Etching Whitepaper

Learn how chemical etching can overcome the limitations of traditional sheet metal machining technologies.

Download