Etch tags: What are they and why are they important?

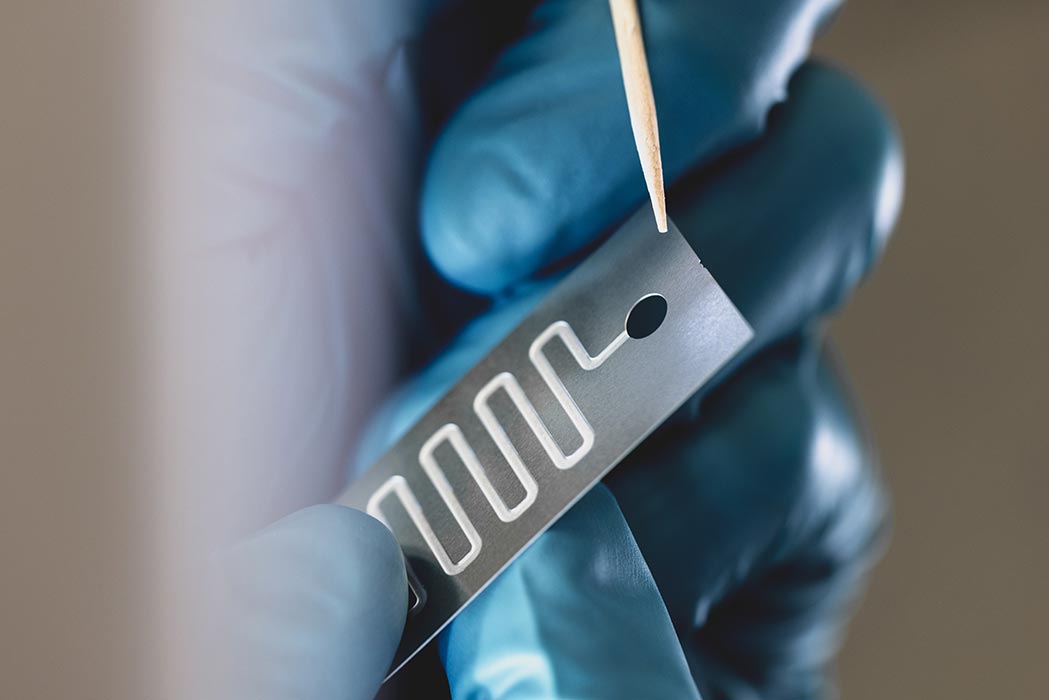

The photochemical etching process is ideal for producing intricate components. Often, the parts we manufacture have extremely tight tolerances and, as such, require etch tags to be added to the outer profile of the design to aid manufacture.

What is an etch tag?

Etch tags, sometimes known as tabs or tie-ins, are threads of metal that are added to the component profile during tooling. The purpose of an etch tag is to allow components to be retained in the sheet during the etching process. They are often required where tolerances are tight, or when parts need subsequent electroplating or assembly.

Once manufactured, components can be supplied to customers tagged into the sheet or removed from the sheet and supplied individually. Subject to the component size, design or tolerance requirement, Precision Micro can offer components without tags; however, they are usually essential when the required tolerance is less than 15% of the metal thickness.

Why are etch tags so important?

- Tighter tolerances: Photochemical etching is the perfect partner for creating parts from thin metals. Etch tags enable us to hold a tighter tolerance during the etching process, often up to ±0.020mm as standard.

- Reduce the possibility of damage in transit: To prevent damage to the products during shipping, etch tags are added to ensure they don’t bend, crease (in the case of thin foils) or rub together and mar the surface finish.

- For subsequent assembly: While Precision Micro offers a service to remove components from the sheet before shipping, tagged sheets can also be directly supplied to customers. This is a great option for higher volume orders that require subsequent assembly or finishing after etching. The etch tags in this instance ensure the parts can be removed from the sheet without damage and make the entire process more cost-effective.

Types of etch tags

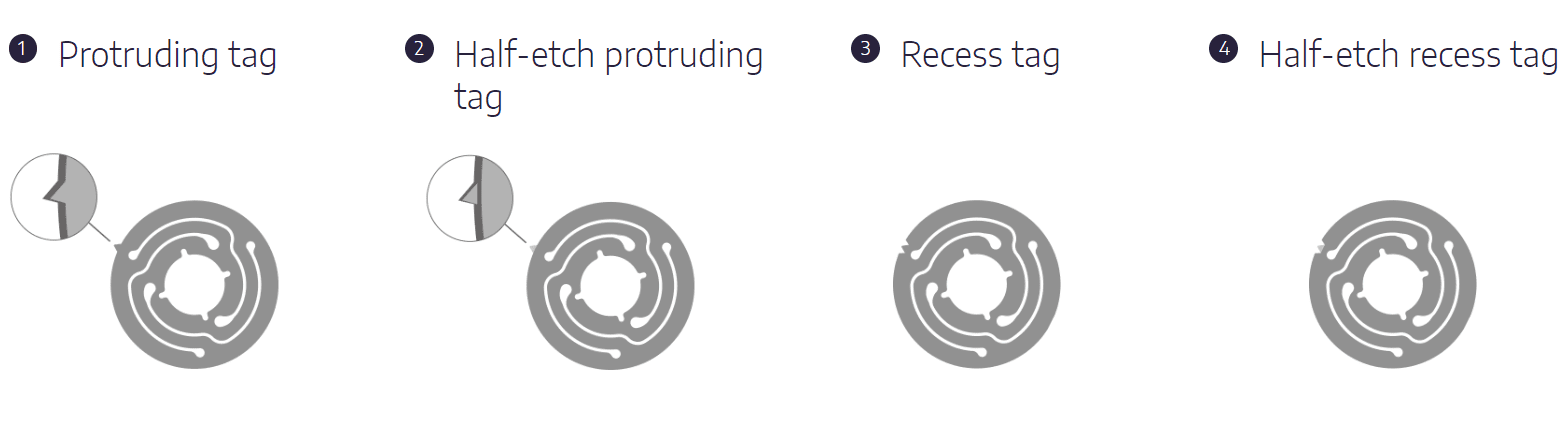

Precision Micro offers four types of etch tag which can be selected based on component geometry, thickness or application.

1. Protruding tags

Protruding etch tags extend from the outer profile. They are the default choice for most components and do not affect the surface of the part.

2. Half-etch protruding tags

Similar to protruding tags, half-etch protruding tags are partially etched in order to ensure easy removal of the component.

3. Recessed tags

Recessed tags are used when a tag protrusion is not permitted, resulting in a small notch in the outer profile of the part.

4. Half-etch recessed tags

Like recess tags, half-etch recess tags remove tag protrusion and aid component removal from the sheet.

Get in touch

Our experienced team can provide advice on the appropriate tag type and location for your design, and how they can be utilised to make production more cost-effective. Get in touch today

Chemical Etching Whitepaper

Learn how chemical etching can overcome the limitations of traditional sheet metal machining technologies.

Download