Chemical etching process: 10 frequently asked questions

Want to ask a question about chemical etching or share a component drawing for technical review?

Q1. What is the chemical etching process?

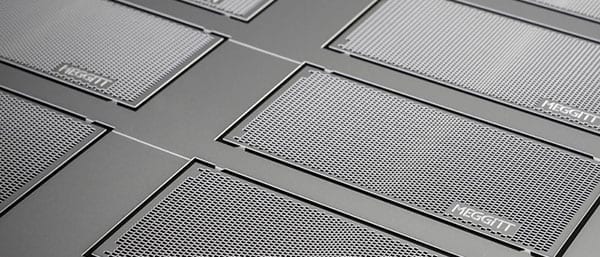

The chemical etching process is a sheet metal machining process that is used to manufacture complex components with high levels of accuracy.

Comprising nine steps, it works by printing the component design onto a photoresist mask which is laminated onto the metal.

The areas of photoresist which have not been printed are developed, exposing the metal, which is subsequently etched away.

Q2. What metals can be chemically etched?

Almost any metal and metal alloy can undergo chemical etching. This includes steel and stainless steels, nickel, copper and aluminium.

What makes photochemical etching so effective is that it works well on hard-to-machine metals, including highly corrosive-resistant metals such as titanium and its alloys.

Q3. What chemical is used in etching?

Most metals are etched using ferric chloride, a safe to use, recyclable etchant. Ferric chloride can be regenerated and reused.

Other proprietary etchants such as nitric acid, are used for specialist metals and alloys.

Q4. What sheet sizes and thicknesses can be etched?

Sheet metals between 0.010mm and 1.5 mm thick can be etched. The thicker the sheet the longer it takes to etch, meaning metals above 1.5mm are uneconomical to process.

Q5. How accurate is chemical etching?

Excellent accuracy can be achieved with photochemical etching. Standard minimum etching tolerances are ±10% of the metal thickness being etched, to a minimum of ±0.025 mm.

With development, greater accuracy can be achieved so it is encouraged that customers partner with Precision Micro early in the design phase so an appropriate etching method can be developed.

Q6. What are the benefits of chemical etching?

Chemical etching is highly advantageous and offers many benefits. This process does not use mechanical force, unlike stamping which subjects sheet metals to extreme pressures. Nor does it put thermal stress on the cutting edge, unlike laser cutting.

Alongside this, chemically etched parts remain flat, burr- and stress-free, leaving the material properties unaffected.

Chemical etching can also produce very accurate engraved features at the same time the material is being profiled, such as fluidic channels, logos or part numbers. These features come at no additional cost.

Q7: What level of detail can chemical etching achieve?

The minimum standard etched opening achievable is 0.1 mm, but with development, etching can achieve even finer features.

Q8. How much does chemical etching cost?

Chemical etching uses digital tooling which is inexpensive, very easy to adapt and does not wear out, unlike presswork tooling.

Material thickness and component size are key cost drivers as you pay by the sheet, not by the part – the more parts per sheet, the lower the unit price. Thicker sheets take longer to etch and this is reflected in the cost of the component.

Q9. What are the maximum quantities chemical etching can produce?

There is no maximum quantity that chemical etching can produce. Low-cost digital tooling ensures prototype quantities can be supplied quickly and economically.

As one of the largest sheet metal etching companies in the world, Precision Micro supplies its customers with component quantities measured in the millions.

Q10. How long does chemical etching take?

Chemical etching lead times are measured in days, not weeks or months, unlike traditional metal machining technologies.

Subject to quantities required and capacity, standard components which require no additional post-processing can be supplied in less than two working weeks. Urgent demands can be supplied even quicker.

Chemical Etching Whitepaper

Learn how chemical etching can overcome the limitations of traditional sheet metal machining technologies.

Download