Electrical Connectors

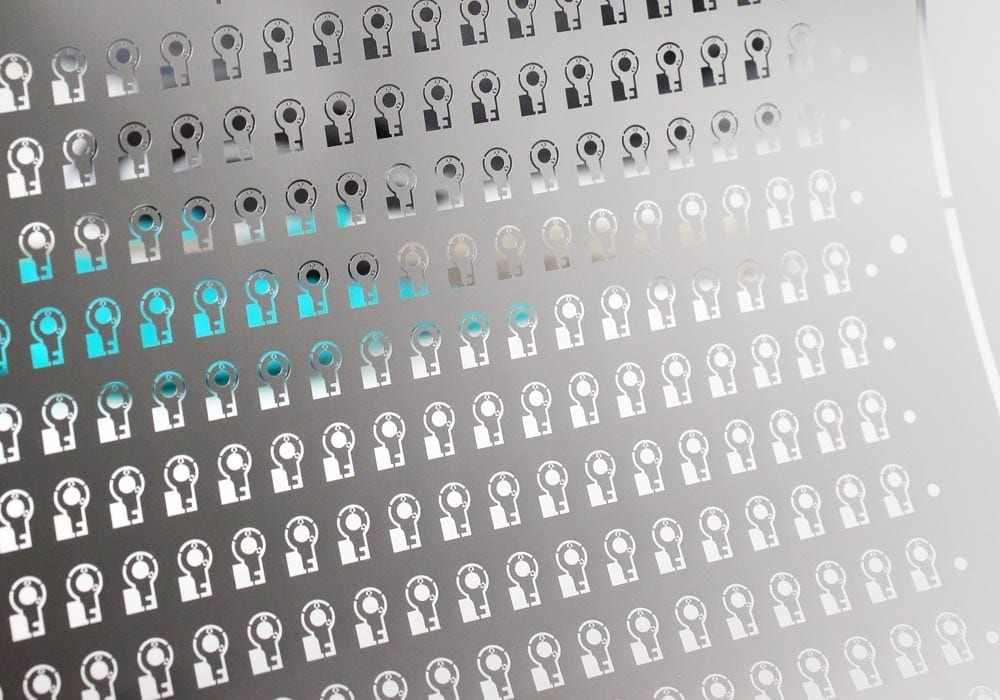

Etched connectors with rapid prototyping and precision.

Request Pricing

With our versatile chemical etching process, we fulfil the electronic industry’s need for custom miniaturised electrical connectors and contacts, free from cost and time constraints.

What are electrical connectors?

Electronic connectors or contacts are conductive metal bridges connecting two points to create a complete circuit. As the demand for smaller devices increases, so does the need for precision-made connectors and contacts. These components are typically manufactured from conductive materials such as copper or nickel, ensuring efficient transmission of electrical signals and power.

Typical electrical connector production

Electronic connectors are traditionally machined using stamping due to the efficiency and speed it provides for large-scale production runs. However, the stamping process does have its limitations. The contact nature of the process introduces the potential for cutting-edge stress and other part deformities, which can adversely affect the performance of the component. Moreover, stamping can face challenges when producing miniaturised components with intricate designs and tight tolerances.

Chemical etching electrical connectors

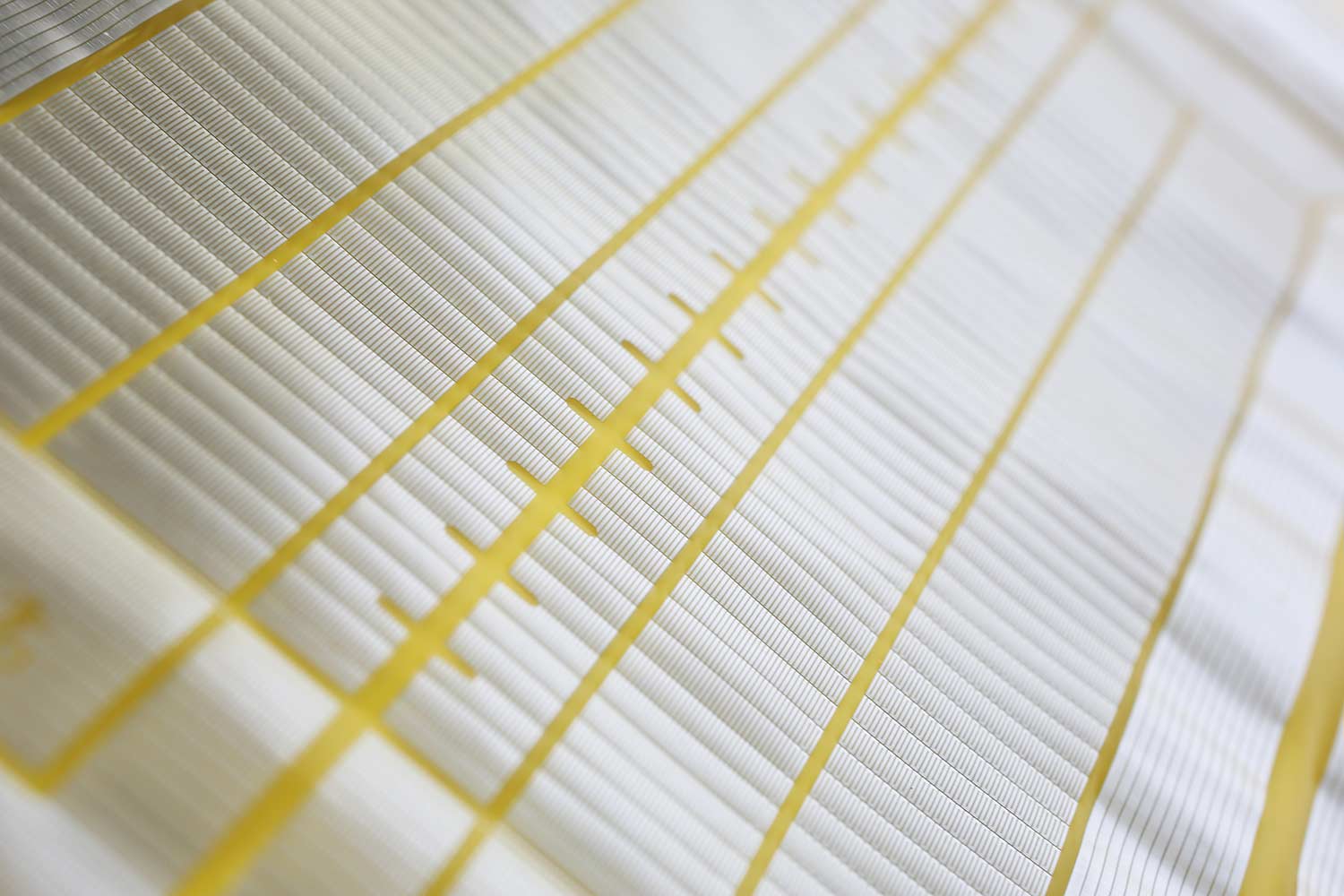

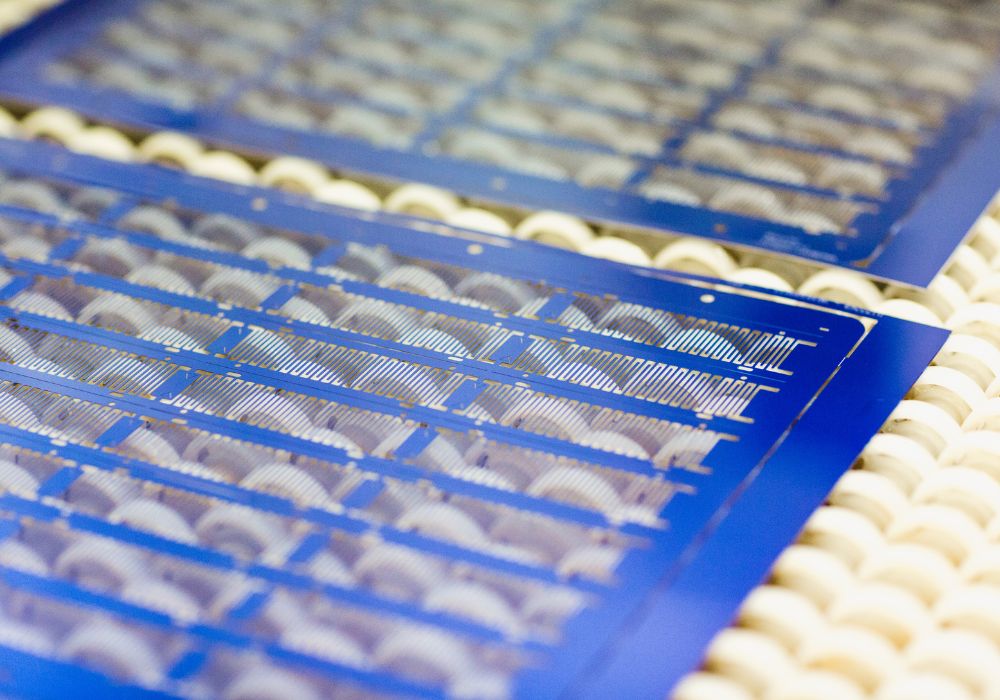

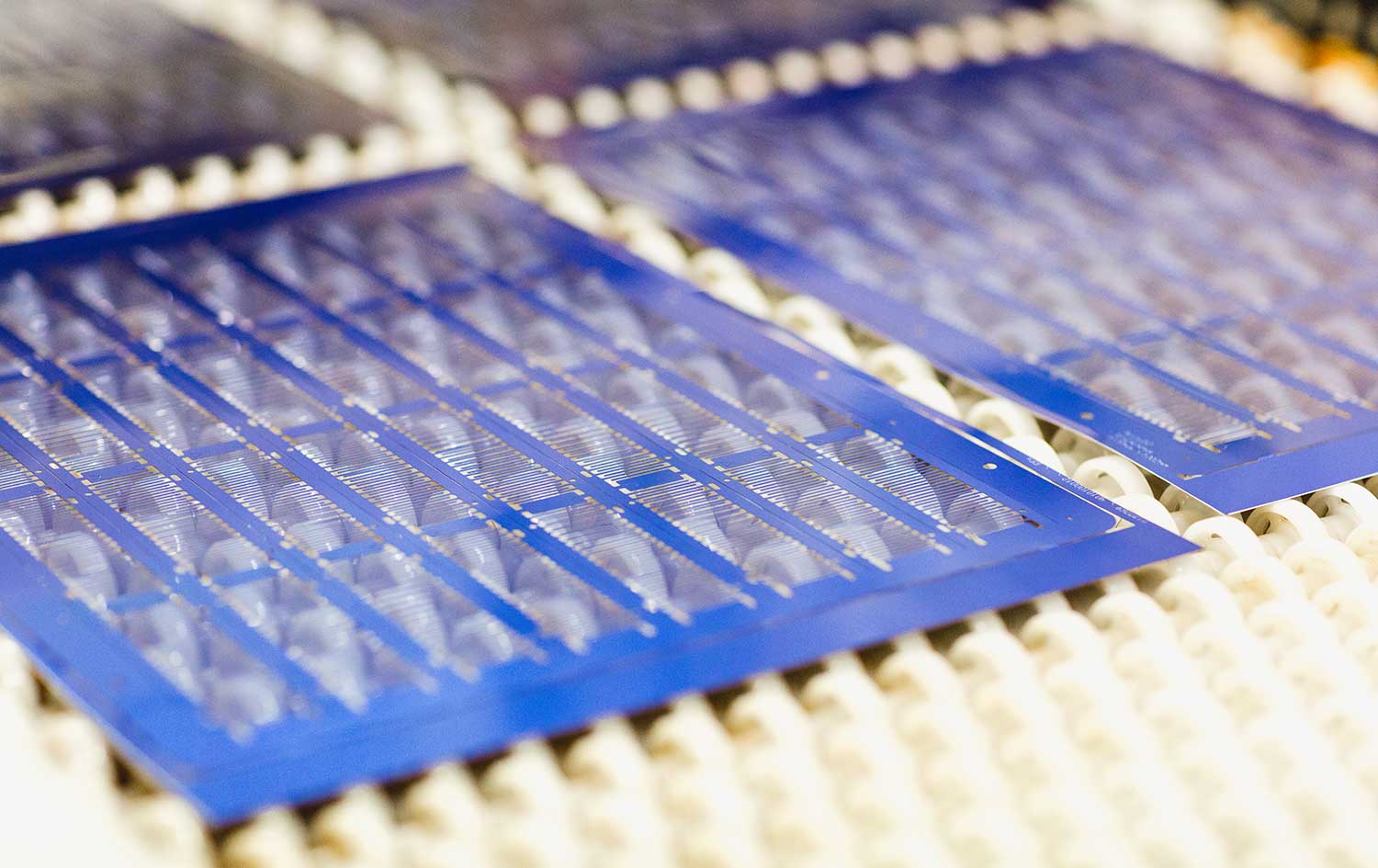

With our pioneering chemical etching process, we produce 100% burr and stress-free electronic connectors and contacts, effectively overcoming the limitations commonly associated with stamping. Moreover, our etching service employs digital tooling, facilitating rapid prototype manufacturing, eliminating the requirement for hard tooling and reducing upfront costs and lead times. With exceptional precision, we can etch micro electrical connectors to ±0.020mm accuracy as standard.

Benefits

100% burr and stress-free

Low cost digital tooling

Rapid prototyping

Accuracy to ±0.020mm

Post-etching services

We provide in-house semi-automated forming, using a range of standard, modular and custom form tools. Additionally, our post-process coatings include gold, tin, silver, tin/lead and sulphur/nickel coatings, enhancing wear resistance and improving part conductivity.

Chemical Etching Whitepaper

Learn how chemical etching can overcome the limitations of traditional sheet metal machining technologies.

Download