Etched metal flexure springs improve Thales’ space cryocooler performance

When manufacturing parts for critical applications, it is vital that the process chosen is not only cost-effective and allows adherence to time-to-market objectives, but is also able to adhere to extremely tight tolerances and is repeatable in production volumes.

Photochemical etching company Precision Micro partnered with Thales Cryogenics for such an exacting manufacturing challenge, the production of metal flexure springs for a satellite cryogenic cooler.

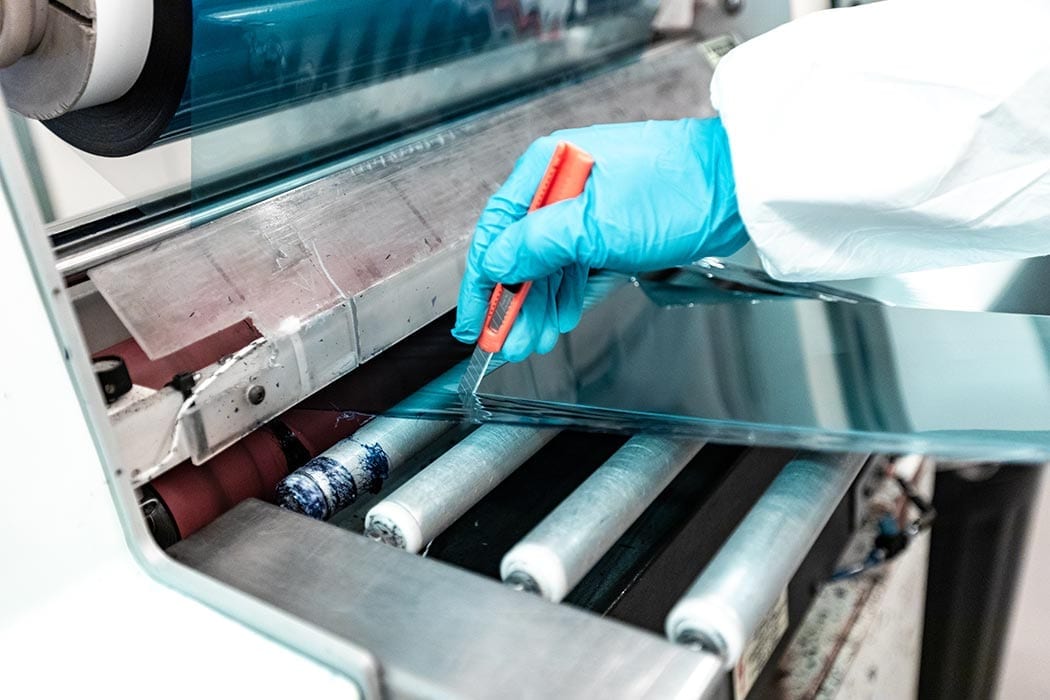

Photochemical etching — the basics

Although chemical etching has been a machining technology for over fifty years, it is still a relatively low profile process, and its practical use in a variety of manufacturing scenarios with an ever-broadening number of materials is one of industry’s best-kept secrets.

Commonly misrepresented as merely a prototyping technology, photochemical etching is, in fact, a versatile and increasingly sophisticated metal machining process, with an ability to mass manufacture complex and feature-rich metal parts and components.

Using photoresist and etchants to chemically machine selected areas accurately, the process is characterised by retention of material properties, burr-free and stress-free parts with clean profiles and no heat-affected zones.

Coupled with the fact that chemical etching uses easily re-iterated and low-cost digital tooling, it provides a cost-effective, highly accurate and speedy manufacturing alternative to traditional machining technologies.

Over half a century of etching innovation

Active in the field for many decades, Precision Micro is constantly pushing the boundaries of what is possible with chemical etching, making advances in etchant chemistry, developing the process to embrace more metals, and increasing accuracy.

It is this pre-eminence that led Thales to partner with Precision Micro in the manufacture of flexure springs used in long-life cooler applications, including those used in space.

Thales Cryogenics

Thales Cryogenics B.V was founded in 2000 but can trace its roots back to the late-1940s when it was a department within the high-tech equipment supplier Signaal USFA.

Today, it is a leading developer and manufacturer of specialised cryogenic equipment, with offices and manufacturing facilities located in the Netherlands.

Its expertise lies in offering the most comprehensive range of cryogenic products for military, civil and space applications.

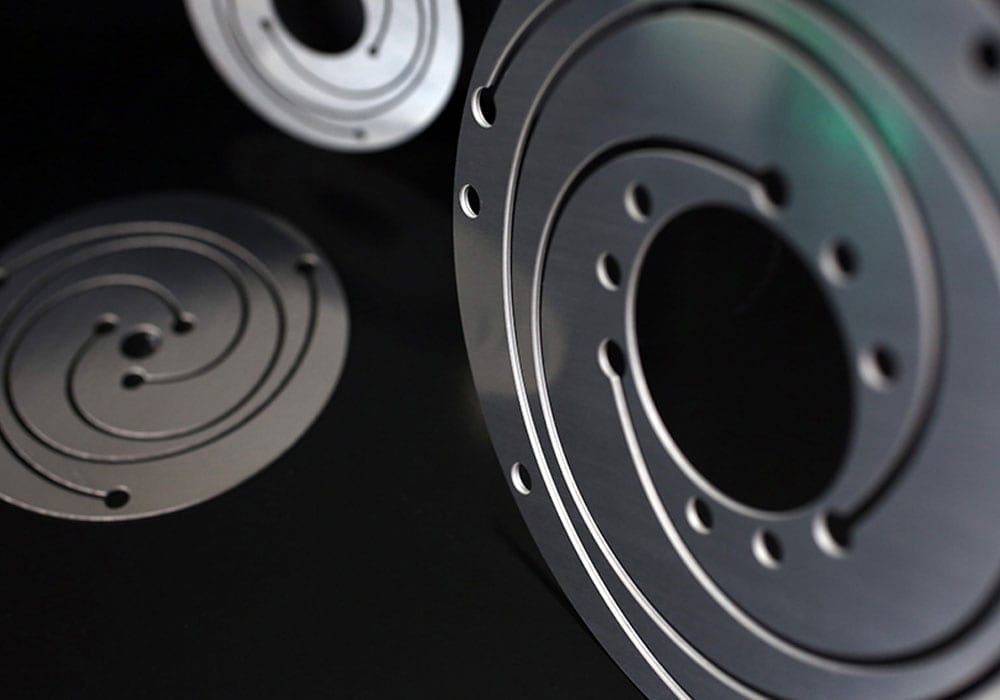

Cryocooler flexure spring development

The critical nature of this component was key in choosing Precision Micro’s photochemical etching process as the preferred manufacturing method.

There is no more extreme environment than space, which demands that parts and components not only work as intended but do so over a prolonged period of time.

As a manufacturing process, chemical etching has one key attribute that sets it apart from other techniques: when it comes to part integrity it does not affect or degrade material properties.

Overcoming burrs and recast layers

The specific flexure spring used in the cryogenic cooler had initially been machined by wire electro-discharge machining, but this left small burrs on the parts and recast layers that would compromise performance.

The process was also expensive, especially when additional post-processing was required to remove burrs.

Accuracy, repeatability and conformance

Whilst cost is an ever-present concern when assessing manufacturing technologies, in niche and highly critical part manufacture this can be superseded by guaranteed quality, repeatability and conformance.

Such considerations were a key concern to the reliability and system lifetime of Thales’ LSF and LPT coolers, which it produces for a variety of customers to cool high-sensitivity sensor systems such as gamma-ray detectors, detectors for thermal night vision and infrared spectroscopy detectors for use in satellites.

Ensuring little to no wear during operation

As these linear coolers contain pistons moving back and forth at around 50 Hz, mounting them on a flexure spring with a radial stiffness and a low axial stiffness is essential for contact-free operation, as it ensures little to no wear occurs during use.

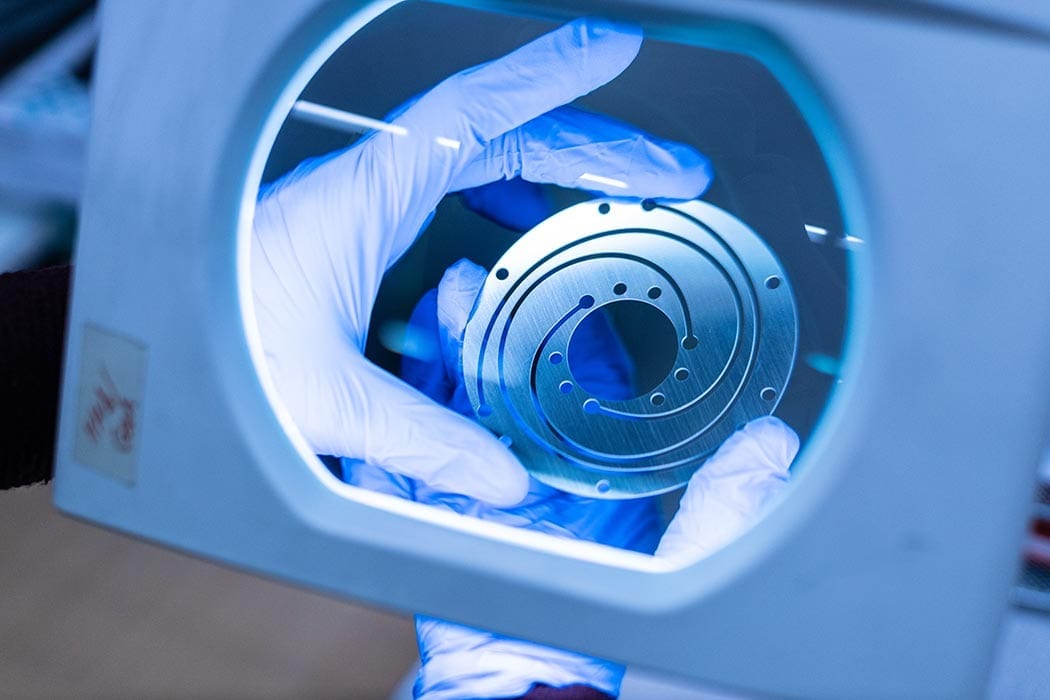

Thales Cryogenics found that flexures made using the chemical etching process met these demanding requirements and retained their properties even after continuous operation.

The purity of the specialist metal grade used in the flexure was vital in ensuring potential fracture sites in the grain were eliminated.

This was only achievable with the burr and stress-free nature of chemical etching and Precision Micro’s wide range of metal etching expertise.

Conclusion

Photochemical etching is precisely suited to applications where the requirement is for small, precise, complex, feature-rich parts with no burrs and no stress-related changes in the metal.

Chemical etching’s use of digital tooling ensures fast, low-cost prototyping that required no revalidation in production.

In the case of the flexure springs produced for Thales Cryogenics satellite cooler, all these attributes combined to make etching the manufacturing process of choice for this especially critical and exacting application.

Chemical Etching Whitepaper

Learn how chemical etching can overcome the limitations of traditional sheet metal machining technologies.

Download