Understanding the crucial role of chemical etching in manufacturing medical precision parts

In the medical industry, precision is not just a luxury; it is a necessity. High-quality, intricate components are essential for various healthcare treatments, from surgical instruments to diagnostic devices.

This article delves into the significance of medical precision parts and the transformative role of Precision Micro’s photochemical etching technology, which offers faster and more accurate solutions than conventional manufacturing methods.

Understanding medical precision parts

Medical precision parts are vital for healthcare applications such as surgical instruments, implants, and diagnostic devices. These components must meet stringent industry quality and accuracy standards, as their precision directly impacts performance and reliability. Any failure in these areas could have serious consequences for patient safety and treatment outcomes, underscoring the importance of advanced manufacturing techniques.

Traditional medical precision part machining

Traditional machining methods, such as stamping and laser cutting, have long been used in the medical field due to their precision and efficiency. However, these methods come with inherent limitations. They often induce burrs and stresses in the materials, reduce versatility, and can impose tolerance constraints. These challenges can lead to longer production times and increased costs, making it difficult for manufacturers to consistently meet the rigorous demands of modern medical components.

In contrast, photochemical etching effectively addresses these challenges, offering numerous advantages for the production of medical precision parts.

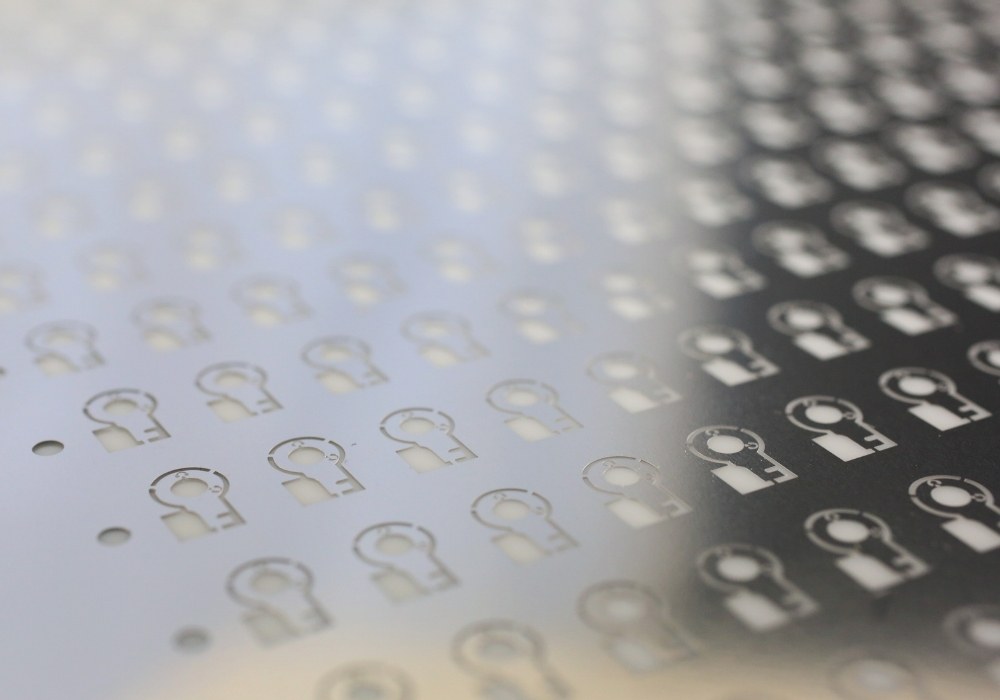

The photochemical etching process

The photochemical etching process begins by coating a metal sheet with a UV-sensitive photoresist. This coated sheet is then exposed to ultraviolet light through a photomask, which transfers the component design onto the surface. The unprotected areas of the metal are selectively dissolved using chemical etchants, effectively removing the exposed metal and creating the desired component.

Burr-free, stress-free, and clean components

One of the most significant benefits of photochemical etching is that it produces burr-free and stress-free components in a clean manufacturing environment. By eliminating the concerns of burrs and stresses commonly associated with stamping and laser cutting, photochemical etching ensures that medical applications are manufactured cleanly and precisely. Unlike traditional machining methods that can generate metal shavings and contaminants, photochemical etching produces a controlled process that maintains the integrity of the components throughout production. This is crucial for medical applications, where cleanliness is paramount and any contamination could jeopardise patient safety.

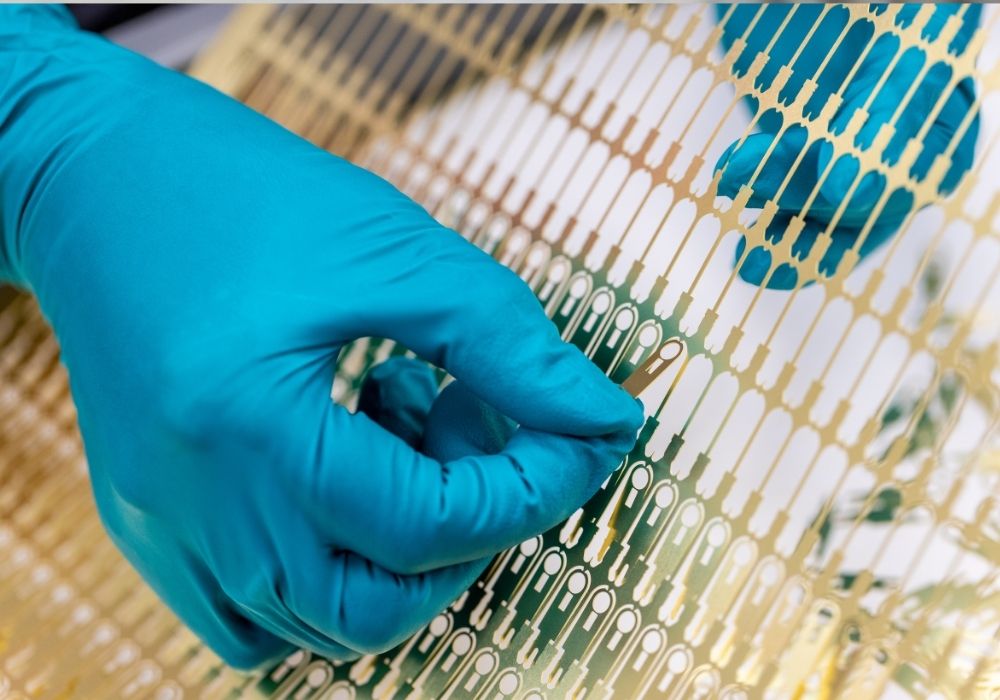

Achieving precise and complex features

Photochemical etching offers engineers unlimited design freedom by utilising photodigital tooling, allowing for the creation of intricate features with sizes as small as 0.1 mm and accuracies of ±0.020 mm. This capability means that even the most complex geometries can be produced without incurring additional costs, making it an ideal choice for advanced medical applications.

Material flexibility

Photochemical etching is a versatile machining process that accommodates nearly all metal types in thicknesses ranging from 0.01 mm to 2.5 mm. This flexibility allows medical device designers to select optimal metals for each component, ensuring that they achieve the best possible strength-to-weight ratios, biocompatibility, and corrosion resistance. While conventional machining often struggles with certain materials, particularly those that are difficult to cut or shape, photochemical etching can handle a wider variety of metals without compromising quality.

Reduced lead times and scalability

Digital tooling enhances production efficiency, reducing tooling and prototyping lead times while allowing for seamless design amendments. As a result, medical parts can be delivered in as little as two weeks of receiving technical data, significantly shortening time-to-market for essential healthcare components. Furthermore, photochemical etching provides scalable production capabilities, making it suitable for both small and large volume runs. This adaptability enables manufacturers to respond to varying market demands without compromising on quality or precision.

Why choose Precision Micro for your medical precision components?

Precision Micro provides medical device designers with a rapid, clean, and cost-effective ISO-accredited chemical etching service that surpasses conventional machining capabilities. Our expertise covers a range of applications, including bone saw blades, electrical connectors used in hearing aids, and surgical filters and screens. In addition to photochemical etching, we offer various post-processing services to enhance performance, all adhering to stringent medical guidelines.

Conclusion

The precision of medical components is critical for advancing healthcare and ensuring patient safety. While traditional machining methods like stamping and laser cutting have their limitations, photochemical etching offers a superior alternative for producing medical precision parts. With unmatched accuracy, material versatility, and the ability to create complex designs at a fixed price, photochemical etching stands out as a vital manufacturing process in the medical field. Combined with Precision Micro’s expertise, this technology enables the creation of innovative, high-quality components that meet the stringent demands of the medical industry, ultimately contributing to improved patient outcomes.

Contact us today about your next medical precision part project!

Chemical Etching Whitepaper

Learn how chemical etching can overcome the limitations of traditional sheet metal machining technologies.

Download