Bipolar plate manufacture: Why fuel cell engineers should consider chemical etching

International pressure on energy diversification has led to a dynamic investment environment for alternative energy options, and fuel cells are close to being the most efficient, with the global fuel cell market set to reach upwards of $25 billion by 2025.

The demand is for more efficient, and increasingly cost-effective fuel cells, which influences both material choice and the chosen technology for manufacture.

International pressure on energy diversification has led to a dynamic investment environment for alternative energy options, and fuel cells are close to being the most efficient, with the global fuel cell market set to reach upwards of $25 billion by 2025.

The demand is for more efficient, and increasingly cost-effective fuel cells, which influences both material choice and the chosen technology for manufacture.

Traditional bipolar plate manufacture

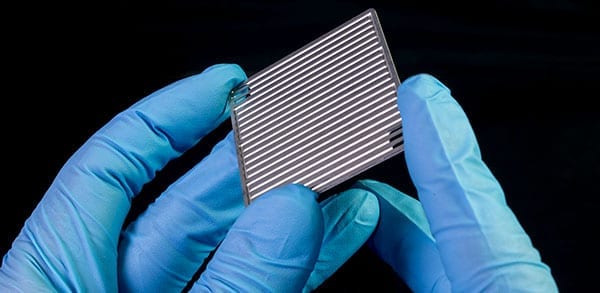

Bipolar plates, a key component of a fuel cell, have traditionally been machined from graphite, an extremely expensive and highly permeable material. So saying, numerous materials have been assessed as alternatives, and because of the demand for competitively priced, relatively-easily to manufacture, durable materials, metallic bipolar plates have become increasingly popular.

Stainless steel, for example, exhibits an array of characteristics that make it ideally suited to bipolar fuel cell plates, including its inherent strength, chemical stability, low cost and relative ease of mass production.

Stamping and hydroforming bipolar plates

Fuel cells are produced by stacking precise and intricate plates machined with complex grooves or channels which enable liquid and gases to flow and can be variously manufactured using CNC-machining, hydroforming and stamping, but there are question marks over these processes.

For example, both stamping and hydroforming compromise planarity (flatness) and introduce stresses and burrs. Tooling can also be slow, expensive and uneconomical to produce, especially during R&D.

Benefits of chemical etching metallic bipolar plates

Photochemical etching process offers manufacturers significant advantages when producing metallic bipolar plates for fuel cells.

Low-cost tooling

First, and most importantly, etching requires no hard tooling, the use of digital tooling being inexpensive to produce and adapt, and therefore allowing designs to be optimised at minimal cost.

Speed of supply

The process allows speedy ramp up from prototype volumes to high volume manufacture, offers almost unlimited part complexity, produces burr- and stress-free components (especially important for fuel cell plates where imperfections can compromise stack bonding), does not affect metal properties, is appropriate for all grades of steel and achieves accuracy to ±0.020 mm — all at lead times measured in days, not months.

Flow field complexity

Chemical etching removes metal simultaneously, meaning complex channels or flow fields can be etched on both sides of the bipolar plate at the same time.

This versatility enables designers to vary the size and shape of channels and incorporate headers, collectors and port features without additional cost.

Suitable bipolar plate metals

Precision Micro typically manufactures bipolar plates from 316L-grade stainless steel in plate sizes up to 1500mm x 600mm, but plates can also be specified in metals such as aluminium or titanium for lighter-weight and improved corrosion resistance.

Summary

The versatility of the photochemical etching process, coupled with Precision Micro’s 60 years of etching expertise, makes it a compelling option for the manufacture of bipolar plates as it removes obstacles for design engineers inherent in traditional technologies.

Chemical Etching Whitepaper

Learn how chemical etching can overcome the limitations of traditional sheet metal machining technologies.

Download