Flat Springs

Engineered with absolute precision.

Request PricingOur chemically etched flat springs can be specifically tailored for engineering applications that demand exceptional precision while avoiding the undesirable effects associated with traditional sheet metal machining methods.

What are flat springs?

Flat springs, distinguished by their flat design, serve as mechanical devices designed to store and release energy. Manufactured from high-grade sheet metals, they come in various shapes and sizes to suit specific applications, often where space is limited or the spring forms part of a more extensive mounting assembly.

Traditional flat spring machining

While flat springs are commonly manufactured through stamping, this method can present certain limitations. For instance, stamping has the potential to deform spring steels, resulting in material stress and burred edges that may lead to fatigue fractures. We recognise that maintaining attributes such as flatness, recoil and fatigue strength is crucial in flat spring production. Therefore, chemical etching emerges as the ideal process to address these concerns and overcome these challenges.

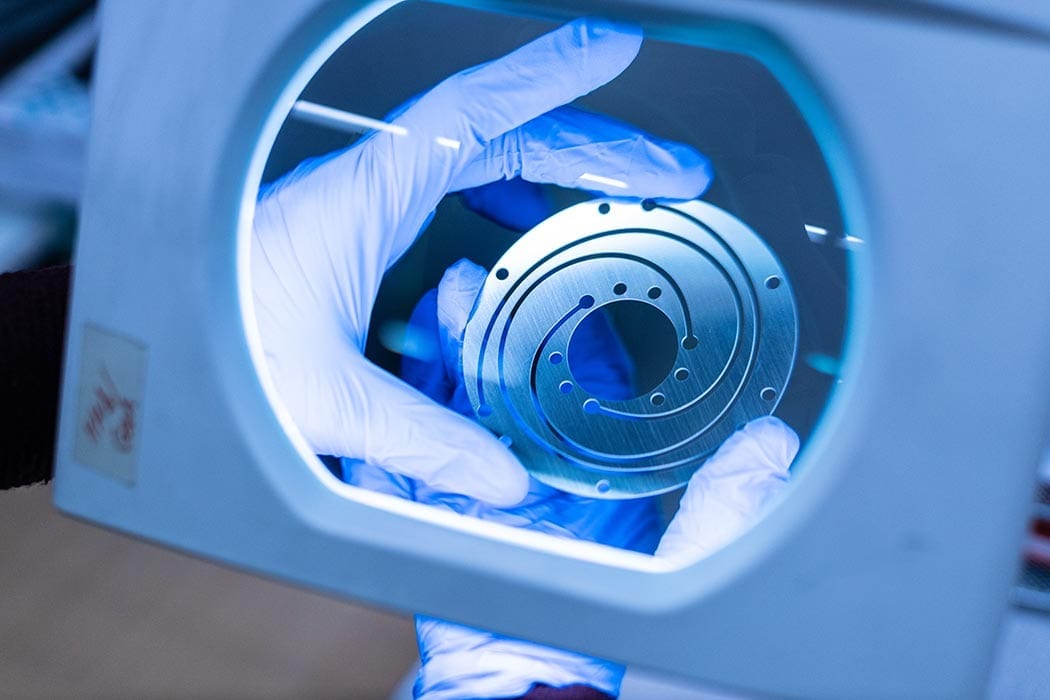

Chemical etching flat springs

Our chemical etching service does not alter the mechanical properties of spring materials – bypassing the limitations of conventional production methods. This means that every flat spring produced is 100% burr and stress-free with zero distortion or material degradation.

Chemical etching is suitable for all spring steel grades, from 301 and 177PH stainless steels through to specialist flapper valve steels alloyed with molybdenum that offer extremely high fatigue strength under bending and impact stress.

Benefits

100% burr and stress-free

Accuracy to ±0.020mm

All spring steel grades

Low-cost protoyping

Versatile production

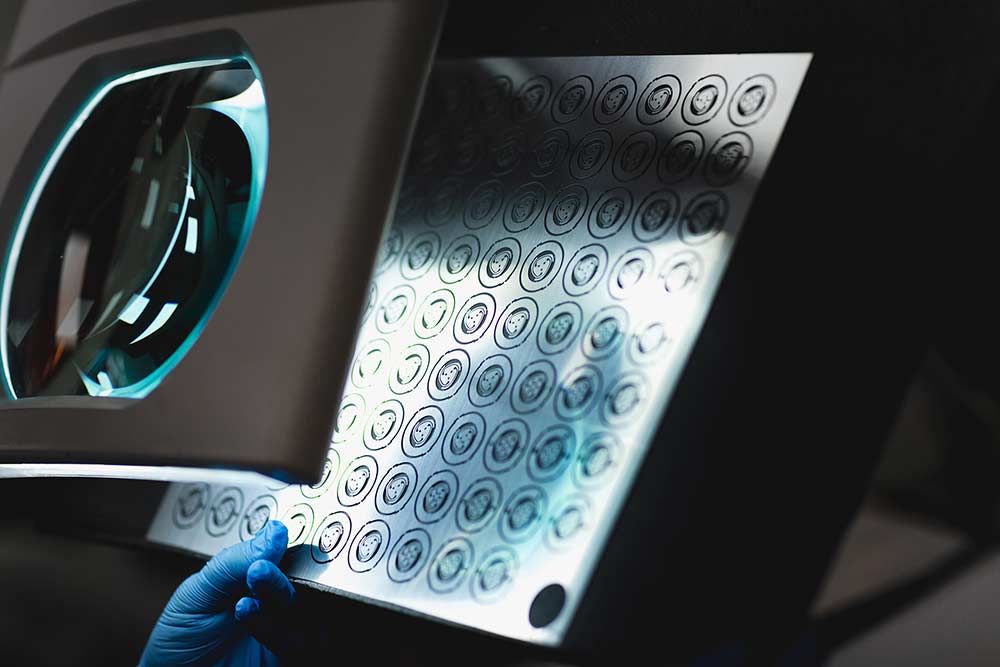

Through the use of digital tooling, we are able to keep set-up costs low and supply prototypes fast – often within just a few days.

We supply specialist flat spring in quantities measured by the million for a diverse range of applications, including:

- ABS braking systems

- Gasoline direct fuel injection

- Catalytic converters

- Satellite cryogenic coolers

- Microphone diaphragms

- VCM camera springs

- Cochlear implants

Many of these spring components started life as co-development projects, with customers benefitting from the low barrier to entry of chemical etching, our material expertise and design support and more than 60 years of chemical etching know-how.

Chemical Etching Whitepaper

Learn how chemical etching can overcome the limitations of traditional sheet metal machining technologies.

Download